In the manufacturing process of glass wine bottles, the melting and annealing stages usually have a greater impact on the environment. The following is a specific analysis:

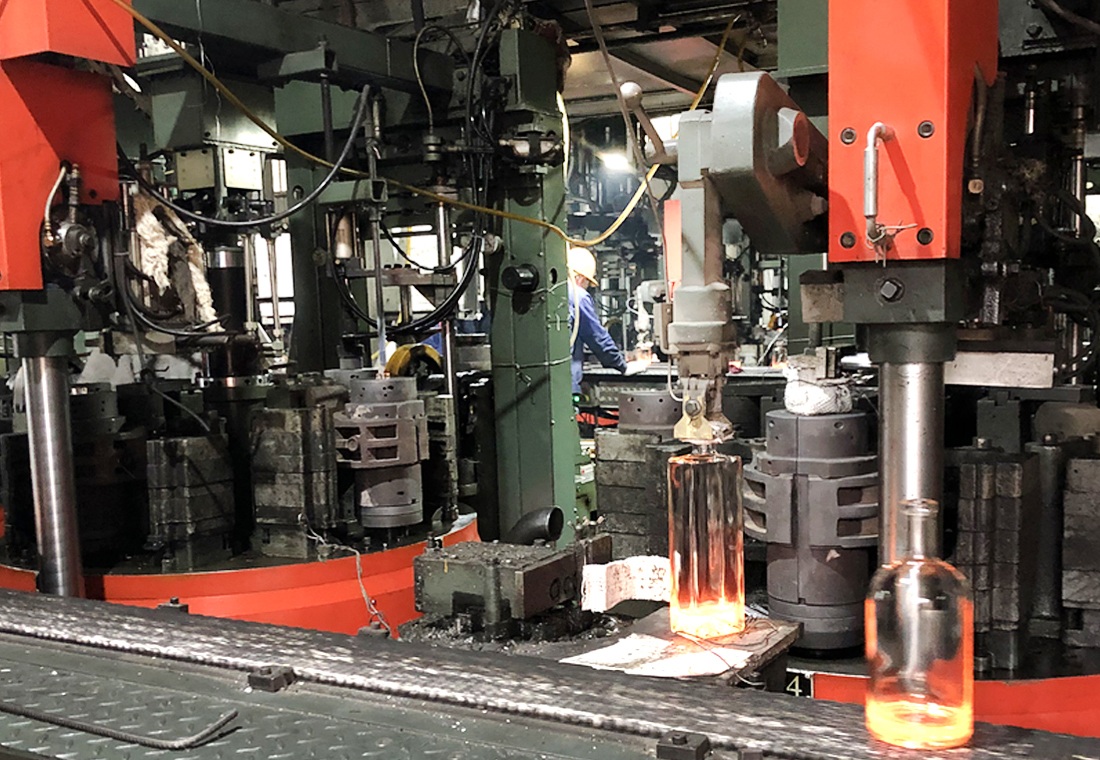

Melting stage

Energy consumption: The melting process requires heating the raw materials to a high temperature of 1500℃-1600℃, which consumes a lot of energy. Generally, heat is provided by burning fossil fuels such as natural gas and coal gas, which will produce a large amount of carbon dioxide emissions and aggravate global warming.

Waste gas emissions: Certain components in the raw materials will undergo chemical reactions at high temperatures to produce harmful gases such as sulfur dioxide and nitrogen oxides. If these gases are directly discharged into the atmosphere without effective treatment, acid rain, chemical smog, etc. will form, causing serious harm to the environment and ecology.

Dust pollution: Dust may be generated during the process of raw material transportation and feeding. These dusts will not only affect the air quality in the workshop and threaten the health of workers, but also pollute the surrounding atmospheric environment if they spread to the surrounding environment.

Annealing process

Energy consumption: The annealing process requires heating the glass bottle to a temperature close to the softening temperature of the glass, and then slowly cooling it. This process also consumes a lot of energy, mainly electricity or heat energy, and will also indirectly produce greenhouse gas emissions such as carbon dioxide.

Waste heat emission: During operation, the annealing furnace will emit a large amount of waste heat to the surrounding environment, causing the temperature in the workshop to rise, increasing the refrigeration load of the workshop, and also causing a certain amount of energy waste. If effective waste heat recovery measures are not taken, these waste heat will be directly discharged into the atmosphere, which will have a certain impact on the local ambient temperature.

However, other links in the manufacture of glass bottles, such as dust emissions during raw material processing and possible pollution caused by chemicals used in processing and decoration, will also have a certain impact on the environment. With the continuous development of environmental protection technology, glass bottle manufacturers can reduce the impact of each link on the environment by adopting advanced furnace technology, installing waste gas purification equipment, optimizing annealing processes, and strengthening waste heat recovery and utilization.